How To Specify Timber Veneer

What is Timber Veneer?

Veneer is a thin layer of natural wood that is sliced and applied to a substrate, such as wooden board, particle board, or fibreboard, to create a decorative surface. It offers a highly efficient way to utilize valuable timber, as one cubic meter of log can produce around 1,000 square meters of veneer, minimizing wastage compared to solid timber.

Some key benefits of timber veneer include:

1. Design Flexibility: Each piece of veneer is unique due to the natural variations in wood grain, creating distinctive finishes that can’t be replicated by man-made materials.

2. Natural Aesthetic: Veneers add warmth, depth, and texture to designs, offering a high-quality, tactile surface that feels gentle to the touch.

3. Prestige and Versatility: Timber veneer is considered a premium finish that adds style and sophistication to furniture, cabinetry, and architectural designs. It can be curved and moulded to fit various shapes and applied to a wide variety of substrates. The different pattern joining techniques, detailing and finishing options mean that every project is unique and bespoke.

4. Sustainability: Timber veneer makes efficient and sustainable use of timber resources. By slicing a single log into timber veneer flitches and then assembling the flitches into sheets (layons) the process maximizes the potential of each piece of wood. Each metre of timber typically provides around 1000 slices.

5. Eco-friendly: As a 100% natural product made from renewable wood sources, timber veneer is an environmentally responsible option that combines the natural beauty of wood with an efficient, sustainable approach to material usage.

Timber Veneer

Applications

Timber veneer panels are suited for use in interior, low wear and dry applications, such as joinery, furniture, doors, wall and ceiling panels. Veneer can be used on kitchen and bathroom vanity doors if the room is properly ventilated and if the veneered panel is properly edge banded and sealed. It can be used in low wear dry horizontal applications such as board room tables and office work stations. Use in areas with very bright light should be avoided and veneered panels should never be used or left exposed to direct sunlight. Veneered panels are generally not suitable for flooring unless specially fabricated and coated. Nor are they suitable for high wear, wet, steamy or very damp or high humidity applications such as kitchen countertops, splashbacks above stoves or dishwashers. Veneers should never be used in exterior applications even if under an awning.

Specifying Veneer

Natural Veneer

Natural Veneer may have natural fractures such as pin holes, knots, gum, figure, mild indentations, slanted curved direction of grain, paling fence effect, different leaf widths, off centred crowns etc. and manufacturing features such as join lines and knife rub marks. These are not defects but intrinsic features of natural wood veneer and it’s processing.

Dyed Veneers

Dyed veneers, whilst more consistent in colour than undyed natural veneer may vary in appearance between logs, within logs, from samples to actual current stock and from images on our website compared to samples or veneer used on a project.

Consistency

The best way to control the appearance of veneers and to ensure best possible matching veneer between different packages is to calculate the approximate square metres and panel lengths required for the project. Then make an appointment to inspect and reserve specific logs/ crates in the suppliers warehouse about four weeks prior to the veneer being required. Alternatively, contact the supplier to have samples or photos of a suitable current log posted to you. For best possible consistency within a project, all natural and dyed veneers should be ordered at one time, identified by the project name, and the same coating should be used across the entire project.

Change in Appearance Over Time

Timber Veneers may change colour over time, and with exposure to natural/ artificial/ UV light, air and excessive heat, just as timber will. This is due to the intrinsic nature of lignin (which comprises about 30% of wood) undergoing natural oxidisation. With dyed veneers like other dyed products the dyes may fade or discolour also.

Appearance

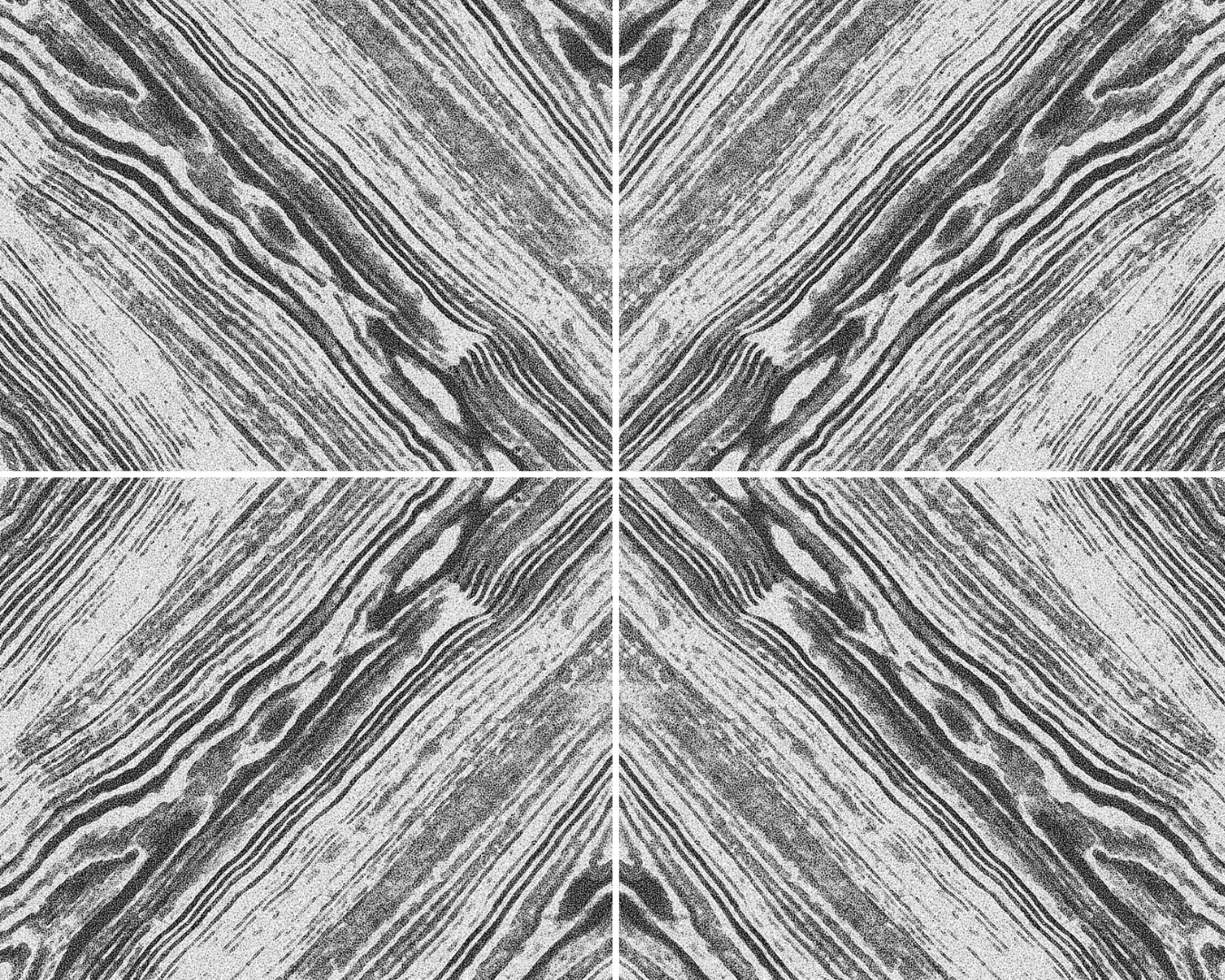

Random Mismatch

Slip Match

Book Match

Reverse Slip Match

Aesthetics

There are many different patterns that veneer leaves can be assembled into a sheet or layon to create different aesthetic outcomes.

The most common methods of assembly for sliced veneer are:

Slip Matched

Book Matched

Random Mismatch

Colour Blended Mismatch

Reverse Slip Matched

In general, with natural veneers, where long sequences or runs of wall or ceiling panelling are required for many species it may be advisable to specify the pattern matching as random mismatch or colour blended mismatch.

In large projects where colour and grain consistency is required, Reconstituted Timber and Dyed Natural Timber Veneer ranges of veneers offer an excellent solution to achieve the desired outcome. If your project requires natural timber veneer or large volumes of any veneer, please contact the supplier to ensure that you are given appropriate technical advice on suitability of the species, cut and pattern matching to achieve the desired aesthetic and application required and so that they can work with you to ensure stock availability.

Matching Patterns

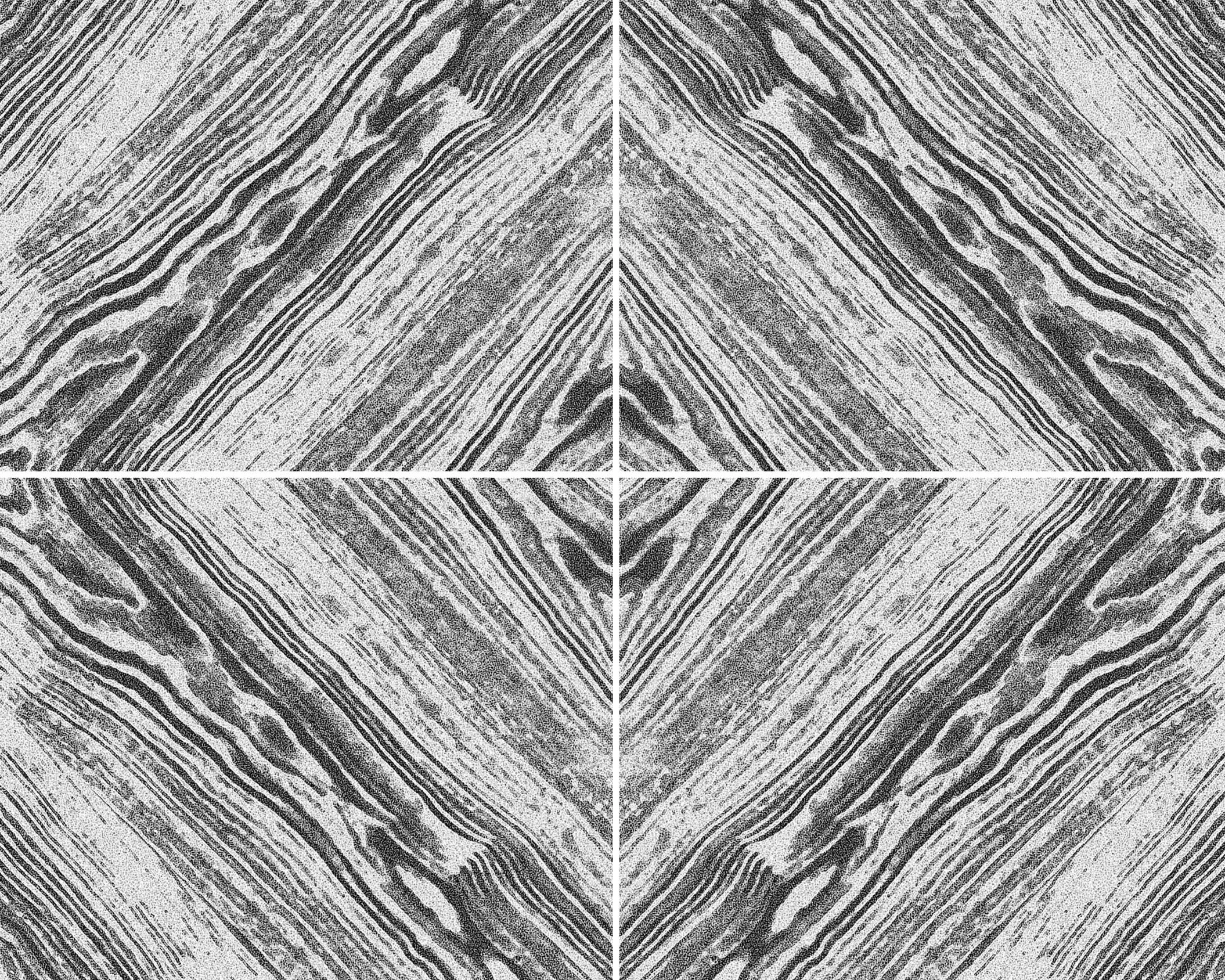

Reverse Diamond

Diamond

Herringbone

Specialty Matching Patterns

Aesthetics

Briggs Veneer has the capacity to manufacture timber veneer layons with artisan & specialty matching techniques such as:

• End Matching

• Quarter Matching

• And other more decorative patterns such as Diamond, Reverse Diamond, Box Match, Reversed Box Match, Herringbone and Sunburst.

Prior to specification and supply it is essential to consult with Briggs veneer for advice on suitability and availability of available material and it is highly recommended that drawings are supplied of the design intent prior to manufacturing.

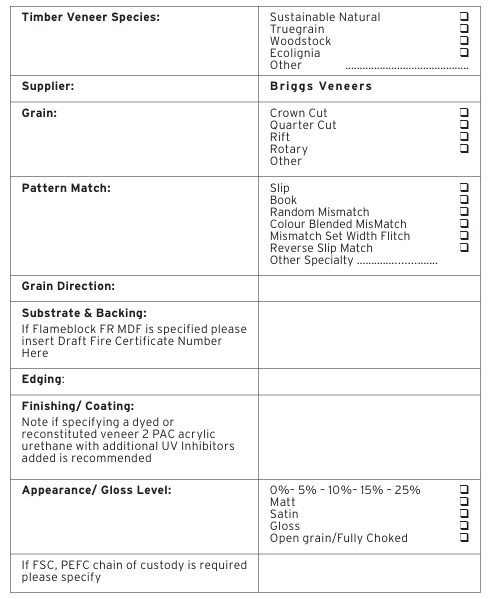

Specifying Notes

Sliced Wood Veneer

Fire Compliance, Sustainability

& Specification Fundamentals CPD

How to Specify Timber Veneer for Wall, Ceiling, & Joinery Applications

Presented by Ruth Przybysz

Timber Veneer Expert - PR AgentZ

This CPD presentation covers innovative techniques and practical applications for both commercial and residential projects. This CPD presentation promises to broaden your understanding and inspire possibilities.

Learning Outcomes:

Gain an understanding of the fundamental properties, attributes, fabrication methods, applications and types of timber veneer.

An in depth understanding of how to specify timber veneer

NCC requirements in Table 3 - Section 4 Specification C1.10

Fire Hazard Group Numbers and Wood Veneers

Sustainable forest Management in Australia and overseas

Environmental benefits of sustainable timber veneer

Independant Forest Certification and how Chain of Custody Works.

To register your interest for upcoming CPD sessions or request a CPD presentation for your Architectural Studio, sign up to PR AgentZ mailing list or contact us directly.